What is NS Code?

Key for environmental and food (product) safety with same system and language – NS CODE

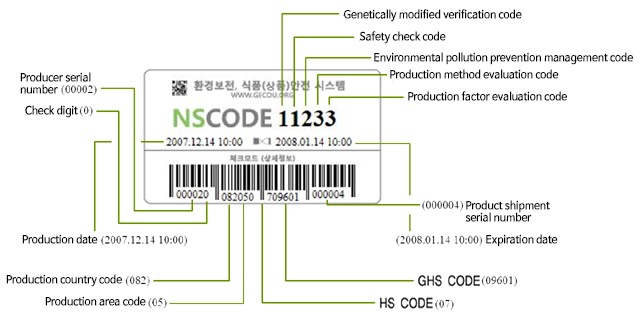

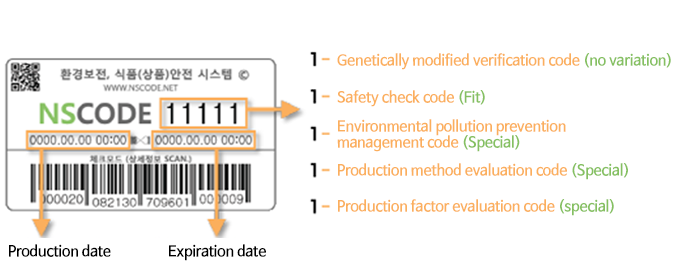

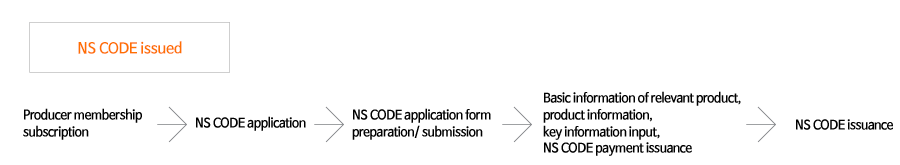

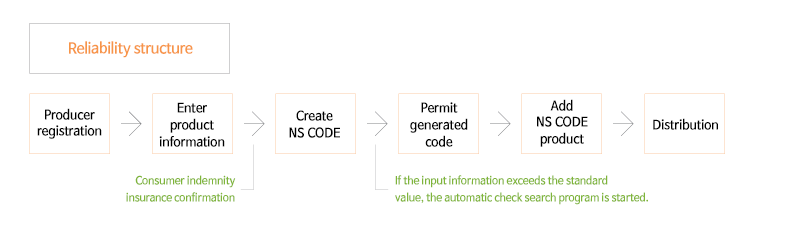

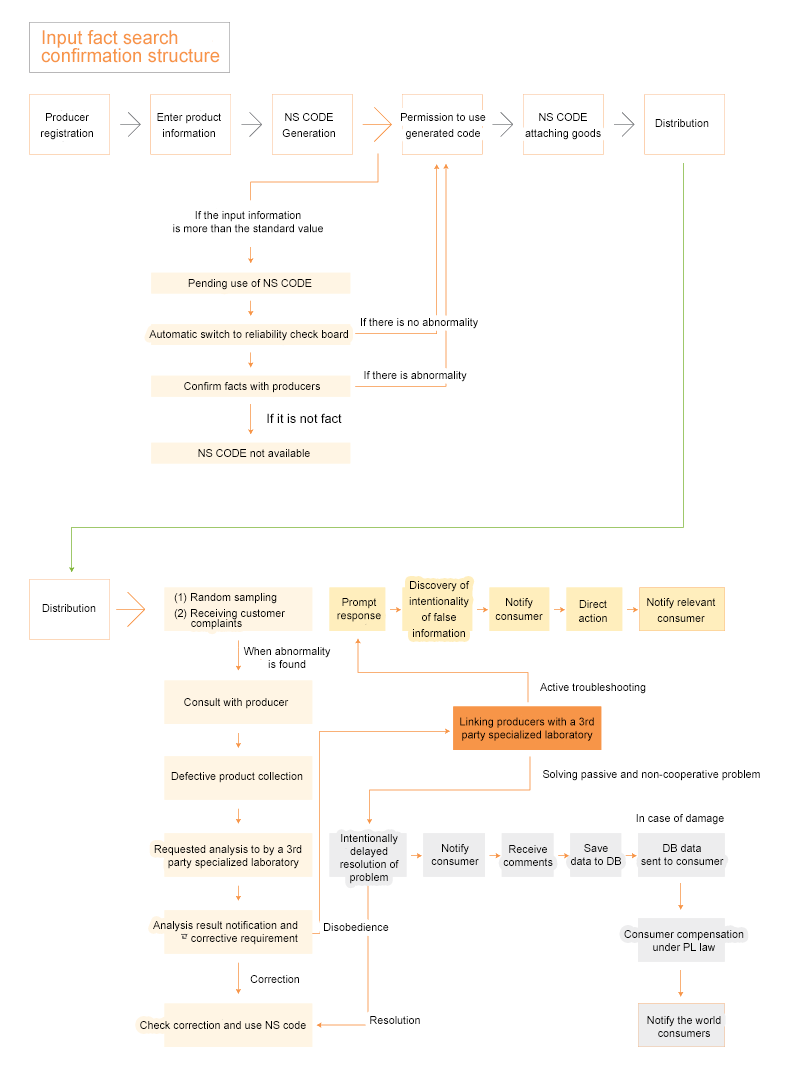

NS CODE is the abbreviation of “New Environmental Protection & Safety Code System” which is an environmental solution code designed to control environmental and food (product) safety issues globally with same system and language directly by consumers worldwide. NS CODE is a consumer focused code that satisfies consumer health and safety environmental requirements of consumers as well as accommodating the existing producer focused barcode system.

Base criteria of NS CODE – HACCP and ISO14000

NS CODE is based on internationally recognized ‘HACCP’ and ‘ISO14000’ for consumer health and environment. HACCP is a risk management standard for food safety, and ISO14000 is environmental management for pollution prevention. The safety of raw materials, the transparency of the production process, the impact of the production process on the surrounding environment and the willingness of the management to preserve the environment are disclosed through NS CODE.

Language calling the environment consumption age – NS CODE

It is the era to change consumption habit that emphasizes quality, price, and service are now time to change. Consumption standards in the 21st century are environment and safety. NS CODE will accompany consumers to preserve the environment and ensure safety. Just by checking the NS CODE, a new economic order centered on environment is created. NS CODE is the language that calls the era of environmental consumption.